Cement Kilns and Their Uses

Most cement is created in a rotary kiln. It is a long cylinder rotating on a slightly angled axis. Completing a rotation once every 1-3 minutes. The cylinder is heated at the lower end where the cement exits the kiln and is allowed to cool. There are two different types of kiln processes used to create cement. They are known as wet and dry.

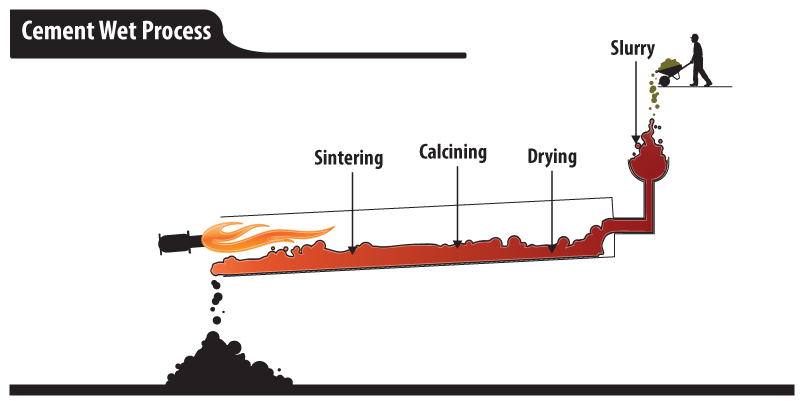

The wet process is the oldest and most simple way to create cement. The raw ingredients used to make cement are added to water and mixed together to form a “slurry”. Adding water to the raw ingredients allows them to blend together more evenly. Once the slurry is ready it is fed through the long wet kiln. It is heated at a high temperature to evaporate the water. The resulting dry “meal” is cement.

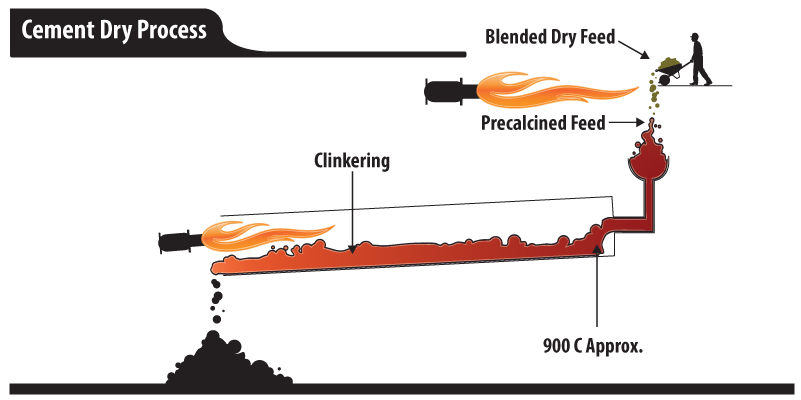

The dry process is the more modern and thermally efficient way to create cement. The raw ingredients are heated and blended in their dry powdered forms. The heated dry ingredients are blended using a series of heated gas cyclones. This is done inside of a preheater tower, or heat exchanger. Once the dry meal reaches the end of the series it is cooled and ready for use as cement.